Сварочные материалы

производство Golden Bridge

MIG / MAG сварочная проволока

Омедненная, полированная (условно аналог СВ-08Г2С, 12.50, 12.51), высокопрочная, медная, алюминиевая

Нержавеющая сварочная проволока

Нержавеющая сварочная проволока 308, 309, 316, 347, включая условно аналоги СВ-04Х19Н9, СВ-07Х25Н13, СВ-04Х23Н6, СВ-04Х19Н11М3

Расходные материалы

для MIG / MAG сварки

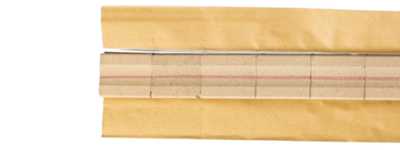

Керамические подкладки

Для сварки толстых листов металла

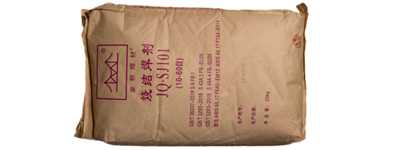

Флюс сварочный

Фторидно-основной (аналог 10.71) и спеченный для нержавейки (аналог 10.99)

Расходные материалы

Горелки MIG / MAG, сопла, кабельные вилки, наконечники, держатели наконечников, каналы стальные, антипригарный спрей, паста

35%

Доля рынка в Китае

Качественные материалы для Вас!

Ведущий производитель сварочных материалов

- Высокое качество

- Надежный поставщик

- Наличие НАКС

- Большой ассортимент

- Непрерывные поставки

- Товар в наличии

400

50

9

5000

Секторы применения

сварочных материалов Golden Bridge

Контакты

Свяжитесь с нашим менеджером

Нужна телефонная консультация?

Позвоните нам

+7 (812) 716-22-39

Наши квалифицированные менеджеры по продажам проконсультируют вас по наличию позиций на складе и подбору аналогов любого из известных брендов, а также помогут выбрать сварочные материалы для специального применения.

Напишите нам

info@novamatik.ru

Если вы хотите получить письменный ответ на ваш запрос, то пожалуйста напишите нам на этот адрес электронной почты или заполните форму обратной связи справа.

Контактная форма

Заполните форму

Отправьте нам сообщение и наш менеджер оперативно свяжется с вами для консультации

Уголок покупателя

отзывы про качество Golden Bridge

Проведено тестирование проволоки в заводских условиях на тавровом и стыковом соединении пластин толщиной 12-36 мм. Визуальный осмотр сварочных швов дефектов не выявил.

Инженер технолог

Флюс сварочный: марки JQ.SJ101 производства Tianjin Golden Bridge Welding Materials Group Со., по технологическим свойствам соответствует требованиям, предъявляемым технологией сварки.

Главный сварщик

— намотка проволоки на катушку качественная, без перехлестов

— стабильный калибр по всей длине, в наконечнике не застревает

— подача проволоки свободная, без рывков

Начальник производства

Сварочные швы по оценке неразрушающего контроля соответствуют заданным характеристикам, обладают хорошей внешней поверхностью, брызгообразование небольшое.